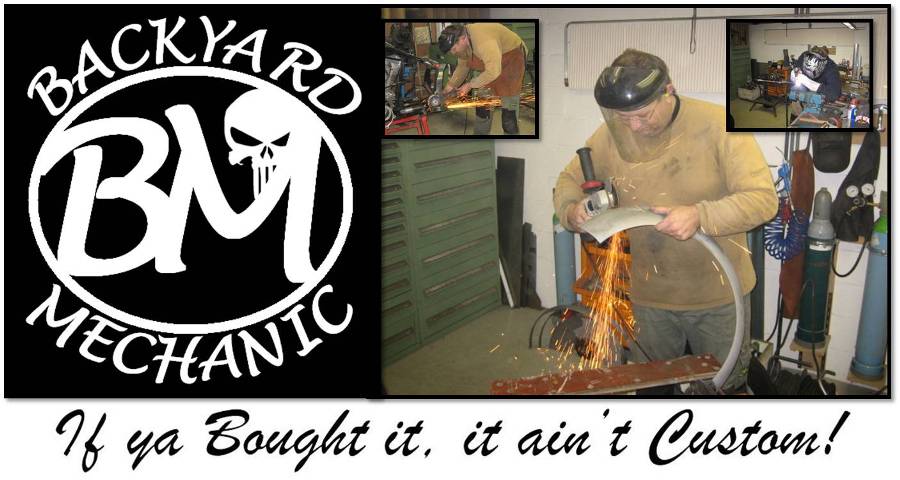

Spend today making a big fat apehanger. The one I had was just to skinny for the bike. Decided to use some thick wall 35mm pipe and to start-up the bending machine this morning....

Made the Ape in parts, which make it easier to make the bends equal from left to right. Took a bit of time and some tinkering, but we got it right in the end.

Had to use Joshua's acetylene torch to shrink one of the bottom bends, which worked out perfectly. Next weekend some final grinding to do, but for now I am very pleased with the result.

This Ape matches the fat look of the bike, the bends are smoother and the build-in risers give it a cleaner look.